NMR testing services really benefitting a Northern Ireland farm

Accessing advanced and accurate management data from genomic tests improves herd efficiency

There’s no standing still for one Northern Ireland producer when it comes to embracing new technology that will promote genetic potential, and sustain productive, healthy and longer lasting cows in an efficient dairy business.

Stephen Morrison and his father David run the 220-cow Holstein Toberanne herd at Armoy, County Antrim, named after the river that runs through the 154-hectare grassland farm. It’s developed into a high production all-round calving herd, regularly scooping up NMR herd performance awards.

Cows are housed and calve all year round. A robotic milking system was introduced in 2014. “This was to save labour and improve cow welfare as yields were steadily rising, so we felt cows needed milking more often,” says Stephen.

Looking to maximise progress and increase efficiency, they started genomic testing heifers in 2019. After six years, all cows in the milking herd now have a genomic test and this has enabled Stephen to take advantage of the service - GenoCells - that can provide individual somatic cell counts simply from a bulk milk sample DNA test.

“Just my father and I manage the herd, and I have three young sons, so the work life balance is important,” says Stephen. “Automation has been key. We’ve also added robotic scrapers, a feed pusher and fans to control temperature. And we’ve streamlined herd management to reduce labour requirements.”

They supply farmer cooperative Dale Farm who reward for solids, so this has been a focus in their breeding plans, alongside improved cow health and longevity.

“Improved production had to be efficient and come from healthy cows and fertile cows,” says Stephen.

The Morrisons use the Clarifide DWP genomic testing service through their vet Adam Conn at Riada Vets. This provides a dairy, wellness and profit (DWP) genomic index to use when selecting animals to breed from.

Using genomic data to select animals to breed from has increased their rate of improvement. “Milk solids have improved significantly in the past six years, and milk yields have continued to increase too. Pre robots the average was 9,000kg a cow,” he adds.

The herd currently averages 12,193kg of milk at 4.31% fat and 3.43% protein. Cows average 3.1 visits to the robot daily.

Belief in the data

Stephen admits that it’s been an interesting journey, and when they started genomic testing, only about 60% of heifers made the cut for breeding replacements. Now most do. “But there are always exceptions, and it’s confirmed the need to believe in the data and not follow instinct which can be wrong,” adds Stephen.

“Just last year we had a heifer that looked the part, but her genomic results didn’t stack up and we followed the data and didn’t breed her to a dairy sire. Sure enough she didn’t get back in calf, and ended up having poor legs and feet,” he says, adding that pre genomics they’d bred from cows that looked good, but their udders dropped by their third lactation.

“Relying on visual assessment isn’t as accurate as genomic tests. Most likely, these ‘good-looking’ cows wouldn’t have been bred from if we’d had their genomic data. During the past six years, we’ve gained a lot of valuable experience to give us the confidence to put a lot of trust in genomic testing.”

Half the milking herd are bred to sexed dairy semen with each mating carefully planned based on sire and dam genomic data. The aim is to produce 90 to 100 heifer calves a year.

The rest of the herd is bred to beef sires and most of these crossbred calves are reared to finishing on the farm. In total the farm carries about 500 head of stock.

Cell counts

Herds genomically tested using the NMR laboratory, which includes Clarifide and other UK genomic service providers, can access individual somatic cell counts for each cow from one bulk milk test. The NMR GenoCells test cleverly matches the SCC with the DNA of the cow.

“This is an attractive option for our robotically milked cows,” says Stephen. “Luckily, our genomic testing is carried by Zoetis with the Clarifide results available to NMR, so GenoCells is available to us.”

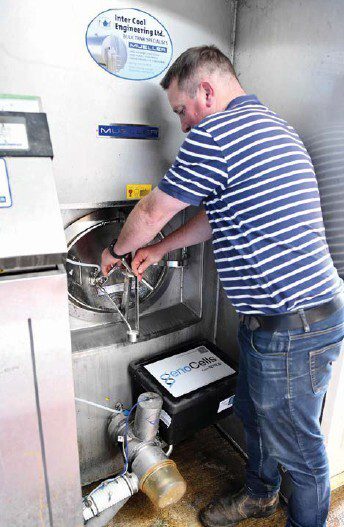

He alternatives each month between GenoCells, where he takes a bulk milk sample himself for SCC testing, with the NMR shuttle service which provides a complete milk recording service.

Milk sampling shuttles are set up on the farm by NMR – one for each robot. The shuttle is attached to the robot for 24 hours to ensure a milk sample is collected from each cow which is then tested and provides individual cow butterfat and protein results, as well as SCC. Every quarter, the sample is also used for a Johne’s screen through NMR’s HerdWise service.

This blended service means that Stephen only has the cost of shuttle hire six times a year but it does provide the required recording information for his pedigree purposes.

“Cell count results via GenoCells and shuttles are very comparable,” says Stephen. “So we can rely on GenoCells as an accurate way of recording our herd’s SCC every other month. And it’s far easier and less time consuming for us.”

Average SCC for the herd is 132,00cells/ml; and any blips in levels are dealt with immediately to mitigate problems. SCC data is also used for selective dry cow treatment. Only 40% of cows receive an antibiotic at drying off, and the aim is to reduce this further. All cows have a teat sealant applied.

“We record all the data through Uniform software and we can soon pick up deviations from our targets,” he adds.

“We’re abiding by strict biosecurity rules, so problems are minimised, and this applies particular to Johne’s control. Our routine screening results shows infection rates are dropping and we’ve only five cows out of the herd with any signs of Johne’s infection.”

Cows are kept on track with a carefully balanced diet, based on a TMR comprising multicut grass silage and wholecrop. Silage samples are tested on a regular basis and diets balanced by Thompson nutritionist Mary-Jane Robinson.

Forages are balanced with a tailored blend for the two batches of cows (high and lows) and each cow is fed to yield with a compound nut via the robots. For example, a 30 litre cow would be balanced for a total crude protein of 16.5% in the overall diet. Annual feed rate is currently running at 4.2 tonnes per cow.

In addition, performance data is monitored alongside body condition score, dung consistency and fertility.

“We’re a high input herd, but we put a lot of effort into getting as much feed value as we can from our own forage,” adds Stephen. “We look for a metabolisable energy (ME above 12 and more than 35% dry matter in grass silage. The aim is to produce a third of the milk from home grown forage.”

Whilst there are no plans – or capacity - to increase cow numbers, Stephen is future-proofing the business by targeting year-on-year improvements. “The aim is to have more cows nudging a tonne of milk solids per lactation through their natural ability and not by being put under any stress,” says Stephen.

“My three sons are already taking an interest, and if they’re keen to keep the business going, we’ve got to maintain progress. There’s some good technology out there. To be successful we’ll need to continue to tap into this.”